With the outbreak of the first industrial revolution, the demand for steel and metal has reached an unprecedented height, and the exploitation of metal ore (non-metal) is also increasing. Huge metal ore (non-metal) must be crushed before processing to further industrial processing, and mining crushing is precisely one of the four major projects of Liming Heavy Industry. Liming Heavy Industry involved in mining crushing for many years, relying on talented scientific research team and rich experience, developed a set of scientific and practical processing of stone/ore production line process.

Stone/Ore Crushing Production Line

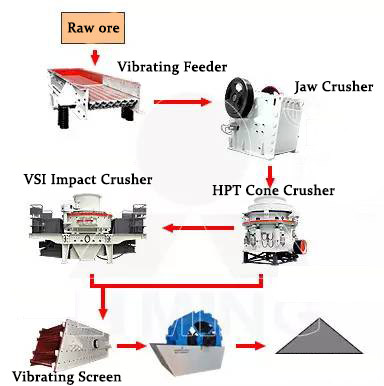

Huge ores from storage bin flows into vibrating feeder which will send them to jaw crusher for coarse crushing. Then the crushed ores will go to cone crusher for medium crushing with belt conveyor. After medium crushing, vibrating screen will screen large sizes of ores out in order to make them crushed again in cone crusher, but required ores will be sent to sand making machine for shaping, and then final products are sent out by belt conveyor.

Equipment recommended

PE Series Jaw Crusher

Features

1. High crushing ratio, well-distributed final product size.

2. Discharge opening of the jaw crusher is adjustable reliably within a wide range through the stuffing of shim, thus it can meet various requirements of customers.

3. Lubrication system of it is safe and reliable, which boasts an easy and convenient maintenance.

4. Simple structure, reliable performance, low maintenance cost.

5. Little dust and low noise.

HPT Series High Efficiency Hydraulic Cone Crusher

Features

1. A high crushing ratio and production efficiency

2. Less spare part consuming and low operation cost

3. Hydraulic protection and cavity clearing, high automatization, reduction of downtime

4. Manifold crushing cavity

5. Easy maintenance and operation

6.The hydraulic cone crusher with high capacity, reliability and flexibility can create more value for customers.

HPT Series High Efficiency Hydraulic Cone Crusher

Features

1.The impeller structure adopts latest four ejection openings, the crushing efficiency is improved about 20% higher than three ejection openings impeller.

2.The impeller parts’ structure and craft are improved. The lifetime of impeller parts is improved about 30-200% longer.

3.The drive part adopts special leak proof structure, which prevent the bearing drum from oil leakage. It acquires 2 national patents. The bearing is imported, and reduces the failure of drive system.

4.Lifting device is convenient for maintenance.

5.Adopt "stone-on-stone" crushing method to decrease kinds of wear part, effectively reduced production cost.

CASES